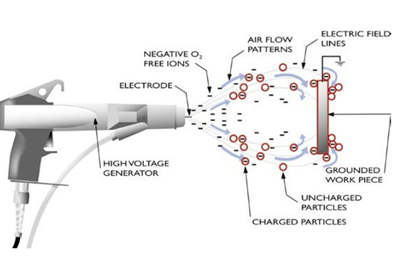

Electrostatic Spray(Corona)

Posted by: FEIHONG Powders |on May 30, 2012

Electrostatic Spray (Corona charging) is the most common method used in powder coating .The process disperses finely ground powder into corona field at the gun tip applying a strong negative charge to each particle. These particles have a strong attraction to the grounded part and deposit there. This process can apply coatings between 20um-245um in thickness. Corona charging can be used for decorative as well as functional coatings. Virtually all resins with the exception of nylon can be applied easily with this process. Making color changes in this type of system varies. Most handgun operators can change over box units in less than 10 minutes. Hopper changes can be as little as 20 minutes if using the same hopper. Color change times for standard systems average between 40-50minutes.

Advantages include : Heavy films ; High transfer efficiency; Applies quickly; Can be automated ;Minimum operator training; Works with most chemistry system.

Disadvantages include:Difficult color changes in automatic systems comparable to tribo systems; Require high voltage source; Difficulty with deep recesses;Thickness control sometimes difficult; Capital cost higher than other methods.

Links to:

D5 Creation

D5 Creation

Comments are Closed