Global Coil Coatings Market Expected to Surpass 6% CAGR during 2016-2020

According to a new market research report released by Technavio, a research institute, the global compound coating growth rate for the global coil coating market is expected to exceed 6% during 2016-2020, which is a significant increase.

The study pointed out that the construction industry is the largest application area for coil coatings (accounting for approximately 76.4%), and it is also the most important factor to stimulate the development of the global coil coating market. In addition, users in the Asia-Pacific region are increasingly interested in water-based polyester coil coatings and are also a factor in the development of the global coil coating market in the construction industry.

Coil coating applications include: construction, automotive manufacturing, home appliance manufacturing, and other industrial areas, the specific analysis is as follows:

1. The annual compound growth rate of global coil coatings in the construction industry exceeds 6.7%. Coil coating is suitable for commercial buildings and residential buildings, protecting the building structure from moisture, UV radiation, microbes, etc. Variety of coil coatings are available. The types of resins used include acrylics, alkyds, polyesters, and the like.

Due to the low VOC characteristics of coil coatings, it is used more frequently in developed regions such as Europe. Moreover, more and more users in these areas are decorating their houses in an environmentally friendly manner, and coil coating meets increasingly stringent environmental regulations, thereby boosting demand for environmentally friendly coil coatings. In addition, the Asia-Pacific region, especially China, is a large consumer of coil coatings and contributes significantly to the development of the global coil coating market.

2. The annual compound annual growth rate of global coil coatings in automotive manufacturing applications exceeds 6%. Coil coatings can improve the appearance and durability of automotive parts and bodies, and eliminate or reduce the external environment’s erosion and destruction, such as ultraviolet radiation, acid rain, pollutants, hot environments, cold environments, road gravel and so on.

The study pointed out that the rapid development of the automobile manufacturing industry in the Asia Pacific region has promoted the development of the global coil coating market. Especially in China, the application of coil coatings in the automotive industry is outstanding and has become a major consumer. Compared to radiation-cured coatings, the ease of application of coil coatings further expands their application. In addition, the continuous in-depth study of water-based coating technology has also promoted the development of the global coil coating market. For example, the Axalta coating system introduced an environmentally friendly vehicle coil coating system that requires no undercoating during construction and uses wet-on-wet coating, eliminating the need for midcoat bake curing.

3. The compound annual growth rate of coil coatings in the application of home appliance manufacturing exceeds 6%. Research indicates that consumer goods and home appliance manufacturing are important downstream industries for coil coating worldwide. Coil coating can effectively improve the appearance, wear resistance, and chemical resistance of the product in this field. For example, coil coatings are used for the surface coating of refrigerator panels and side panels, dryer drums, air conditioner casings, and washing machine covers in home appliances.

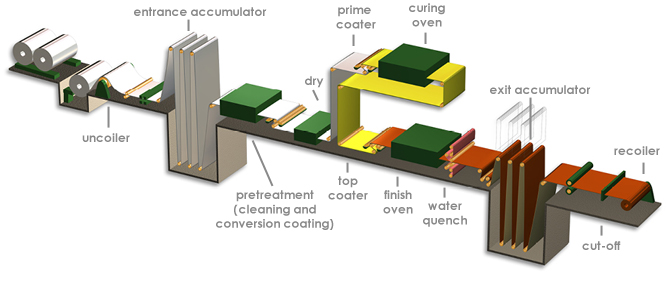

Coil Coating Process

4. Coil coating is also used in other applications such as furniture industry, packaging industry and so on. Among them, household products include cabinets, wooden floors, doors and windows, etc. In general, the growth rate of the furniture industry is 3% to 5%, which is a good factor for the development of the coil coating market; the packaging industry involves iron and aluminum foods, For beverage packaging materials and other metal packaging materials, the annual compounding growth rate of the global packaging industry is expected to be approximately 3.4%, which also has a certain boosting effect on the coil coating market.

D5 Creation

D5 Creation

Comments are Closed